Project Profile

Seismic Hazard Risk Management for Major Petrochemical Company

Learn how we developed a proactive hazard risk management solution to help a major petrochemical company quantify and manage seismic risk exposure across its portfolio of assets.

Project Objectives

#1

Calculate the seismic hazard level at a major petrochemical company's specified facility sites

#2

Quantify the seismic risk exposure for buildings, process plant equipment, utilities and tanks

#3

Make suitable recommendations in order to address the observed/calculated vulnerabilities

#4

Produce detailed engineering designs and calculations to provide solutions for the vulnerabilities

Project Overview

A major petrochemical company needed to requantify and reanalyze the potential exposure of its assets to seismic hazards following an update to the Seismic Building Code of the country where its major assets are located. Once the company's seismic risk exposure was determined, the client also sought engineered solutions to mitigate potential vulnerabilities.

ABS Group was selected to analyze seismic risk across the petrochemical company's global portfolio of assets. The client specifically wanted to know the calculated seismic hazard level at each location, potential vulnerabilities to buildings, process equipment and utility installations, engineering calculations to verify the seismic withstand of key plant items and engineered design solutions to address the observed and/or calculated vulnerabilities.

The output from our risk based studies allowed the client to address the observed vulnerabilities and implement the engineered solutions put forward by ABS Group. Ultimately, this has enabled the company to increase operational resilience and reduce its exposure to seismic hazards that could impact health, safety and the environment as well as disrupt business processes.

Client Needs

- Understand and quantify seismic hazard at multiple facility sites

- Increase awareness of business and safety critical vulnerabilities

- Recommendations to address observed and calculated risks

- Detailed engineering designs and calculations to address recommendations

- Support and monitor recommendation process through completion

Our Solutions

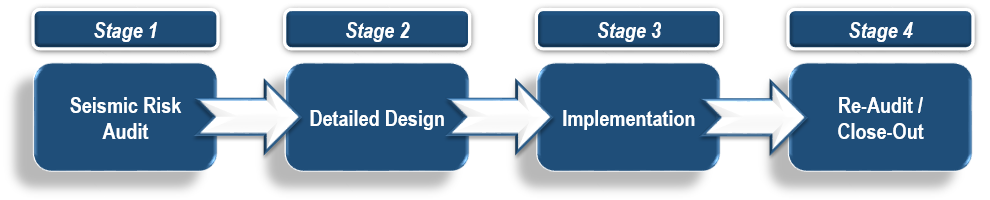

We developed a Seismic Hazard Risk Reduction Program for the client that consisted of four (4) key stages:

Stage 1: Seismic Risk Audit

ABS Group's engineers utilized the seismic building code for the country where the facility was located to calculate the seismic hazard at the facility location. We calculated the seismic hazard design response spectra, which would be used by the engineers conducting the facility audit when assessing potential vulnerabilities.

We then undertook a detailed site-wide facility audit in order to review the buildings, process plant and equipment, utility installations, storage tanks and key emergency systems. The information gathered during the facility audit fed directly into the engineering calculations performed against the seismic hazard at the facility, while allowing our engineers to review the original design criteria adopted.

The output from this stage of the project gave the client:

- Calculated seismic hazard level for the facility location

- Detailed facility-wide vulnerability assessment

- Critical review of the original design criteria adopted at the facility

- Calculation assessments of critical plant and building items, identified as vulnerable during the facility walkdown

- Recommendations to mitigate future risk.

Stage 2: Detailed Design

The purpose of Stage 2 was to build on the data collated and subsequent analyses performed in Stage 1. This enabled us to provide the client with detailed engineering design solutions to address the recommendations made during the first stage, thereby allowing the company to systematically reduce its vulnerability and increase resilience at the facility.

The specific outputs from Stage 2 were:

- Detailed design calculations

- Construction drawings; and

- Specifications and method statements.

Stage 3: Implementation

Stage 3 provided the client with an appropriate level of site supervision in order to implement the detailed designs produced during the second stage, ensuring that the Stage 1 recommendations were effectively closed out.

Stage 4: Re-Audit / Close-Out

The fourth and final stage of ABS Group's Seismic Hazard Risk Management Program involved the re-audit and official close-out of the actions raised during the preceding stages. The re-audit in Stage 4 included assessing new installations at the facility, which were installed after the original audit.