Project Profile

Facility Siting: Fan Pressurization Testing for Shelter-In-Place Buildings

Read how we address complex facility siting hazards, including mitigating the risk of toxic/flammable gas infiltration into Shelter-In-Place buildings at petrochemical facilities.

Project Objectives

#1

ABS Group's engineering services assist in the evaluation and design of remediation for fire, explosion and toxic hazards as part of facility siting.

#2

We apply advanced analysis techniques as part of our blower door testing services to mitigate the risk of toxic/flammable gas infiltration into Shelter-In-Place buildings.

#3

This solution delivers more accurate information to help clients make decisions on building and mechanical system upgrades that often result in cost savings.

Project Overview

Facility Siting addresses explosion, fire, and toxic hazards to occupied buildings. This project profile describes how our Extreme Loads and Structural Risk division provides blower door testing services to mitigate the risk of toxic/flammable gas infiltration into Shelter-In-Place buildings at petrochemical facilities.

A site emergency response plan may call for Shelter-In-Place (SIP) in some situations where there is the potential for the building to be exposed to toxic and/or flammable releases.

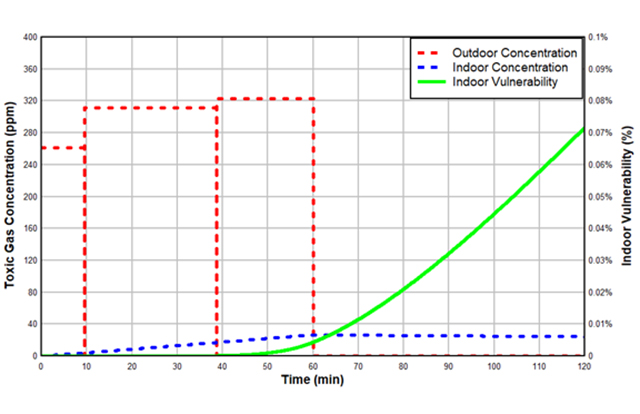

Emergency response planning may direct personnel in SIP buildings in the event of a toxic/flammable release. Often, this SIP practice can be as simple as 1) close doors and windows, 2) shut off the HVAC and 3) wait out the hazard. The hope is that the exterior hazard is neutralized prior to the environment inside the building becoming hazardous.

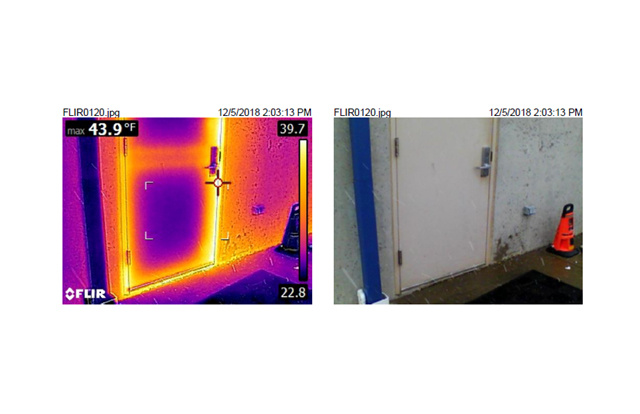

ABS Group evaluates toxic/flammable infiltration into buildings through analysis and fan pressurization testing to quantify hazards when conducting facility siting for shelter-in-place.

Client Needs

- Quantify and understand SIP conditions and hazards.

- Perform fan pressurization testing (blower door testing) to measure leak rate under various conditions.

- Predict toxic/flammable gas infiltration to determine emergency response timing for SIP.

- Safeguard personnel through risk reduction and improving process safety performance.

Value Delivered

Our Facility Siting services cover a wide range of explosion, fire and toxic release hazards that pose a threat to refining, petrochemical and specialty chemical process installations.

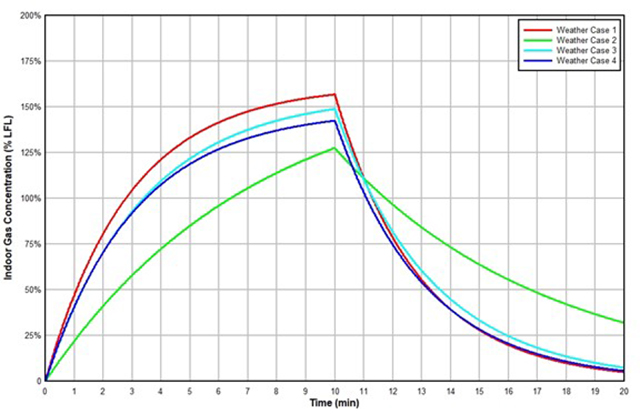

Employing blower door testing and gas infiltration calculations refines the typical, conservative assumptions made in facility siting studies. This provides our clients with more accurate information to make decisions on building/mechanical system upgrades and often results in cost savings. This service also provides a baseline for development of actionable recommendations and remediation for the hazard.