Insight

Hydrogen Fuel: What You Need to Know

EMEA Regional Focus: Safety, Risk and Compliance

Hydrogen (H2) as a fuel has sent a ripple through the industry as a cleaner energy source to reduce the reliance on fossil fuels. With a legal requirement for carbon emissions to reach net zero by 2050 in Europe, H2 is coming back into the mainstream. While this shift to an emerging market represents many economic and climate change benefits, there are important Process Safety Management (PSM) considerations that must not be overlooked.

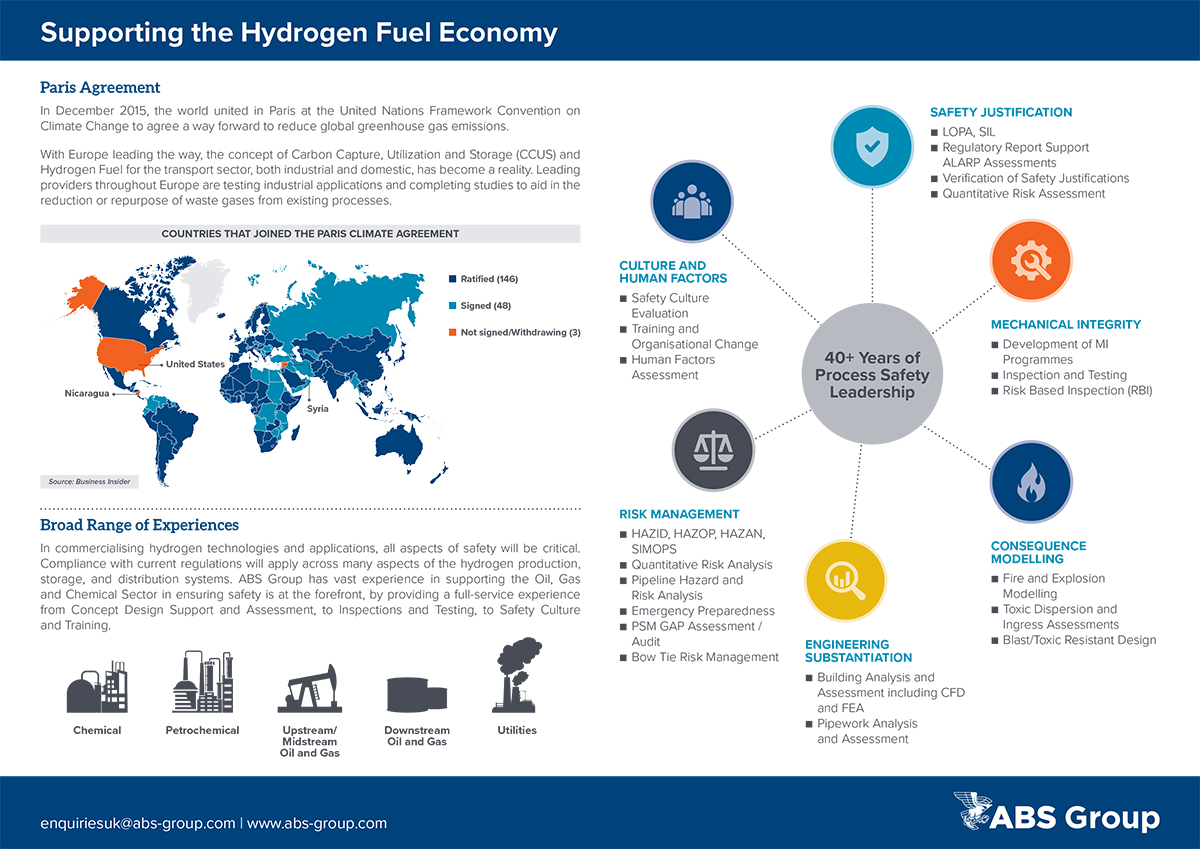

Here are four (4) risk-based considerations for hydrogen fuel projects. View associated infographic

4 Key Areas for the Emerging Hydrogen Market

1- Technical Considerations

Although hydrogen can be produced with minimal climate warming emissions, pollution or smoke, the consequences of fire or explosion from a loss of hydrogen containment can be catastrophic.

Having a key understanding of the unique physical and chemical properties of hydrogen is essential when implementing safety management solutions to support your operation.

Hydrogen has a wide flammable range and an extremely low ignition temperature, along with an invisible flame. The possibility of ignition will always be present, hence most incident prevention measures are likely to centre around leak detection and preventing loss of containment events. Therefore, hazardous area classification for the safe location of electrical equipment is critical.

With the potential for hydrogen to cause significant vapour cloud explosions (VCE) and fires, operators must strive to reduce these hazards to occupants housed within their onsite buildings, commonly undertaken as part of an Occupied Building Risk Assessment (OBRA). Building vulnerabilities need to be appropriately evaluated in the OBRA to accurately determine the response of the structure so that cost-effective mitigation strategies can be implemented.

2- Construction and Commissioning

When a new hydrogen or CCUS facility or unit moves from the design stage to construction and commissioning, both inspection and witnessing of pressurised equipment to PED/ASME standards are recommended. These mandatory standards ensure the equipment complies with EU regulations; however, the use of the equipment is covered by national regulations specific to each country. Once operational, the integrity of mechanical assets within the facility will also be an important feature in the ongoing maintenance. Asset Integrity Management (AIM) could help to expand the lifecycle of any plant by several years, increasing the profitability.

3- Guidance and Standards

As the hydrogen economy progresses, regulations and standards continue to change. One advancement that is occurring from the booming Hydrogen fuel market is the advancements with carbon capture, utilisation and storage (CCUS). Formal guidance for this is not yet available, however, it is important to be aware that standard CO2 pipeline regulations will not necessarily be enough to ensure safety when storing underground. It is important to stay up to date with legislative changes which can be found on your national health and safety regulator's website.

There are however, already established safety standards for refuelling stations handling hydrogen fuel or hydrogen combined fuels. ISO:19880 sets out the minimum design requirements and safety recommendations for both public and non-public hydrogen refuelling stations.

4- New Investments in Alternative Fuels

Over the last few months, Governments in the UK and Europe have already committed significant investment into the research and development of Hydrogen production, storage, distribution and most significantly the carbon capture processes. The hydrogen economy is ever changing, and organizations participating in the future of the world's efforts to reduce the carbon footprint will need to keep pace with emerging markets for alternative fuels.

This article was adapted from the Autumn 2020 issue of Elements, a publication of Chemicals Northwest.

Infographic: Supporting the Hydrogen Fuel Economy