Insight

Facility Siting: Risk-Based Solutions and Benefits

Extreme Loads and structural risk

Facility Siting is part of the Process Hazard Assessment (PHA) requirement in Process Safety Management (PSM) per CFR 1910.119. API 752/753/756 provides a recommended practice for how to perform a facility siting study.

There are many approaches to facility siting which ultimately fall under two categories: Consequence or Risk-based. A risk-based approach to facility siting, which considers the frequency of scenarios, can provide the greatest understanding of on-site risks and enables the most cost-effective resolution of facility siting issues.

ABS Group's experience in consequence and risk-based facility siting assessments, hazard mitigation and structural engineering provides a one-stop solution to risk-based assessment and hazard mitigation.

What is a Quantitative Risk Assessment?

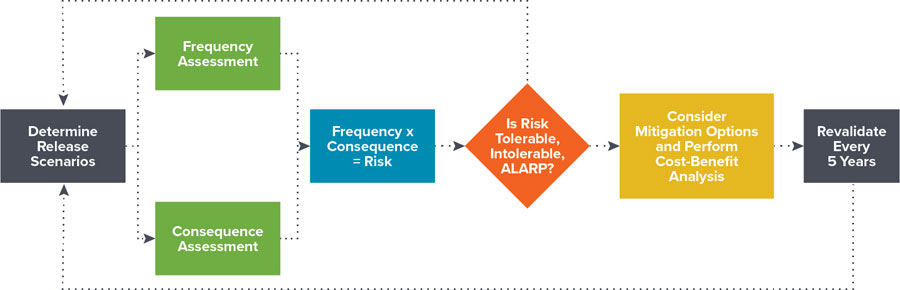

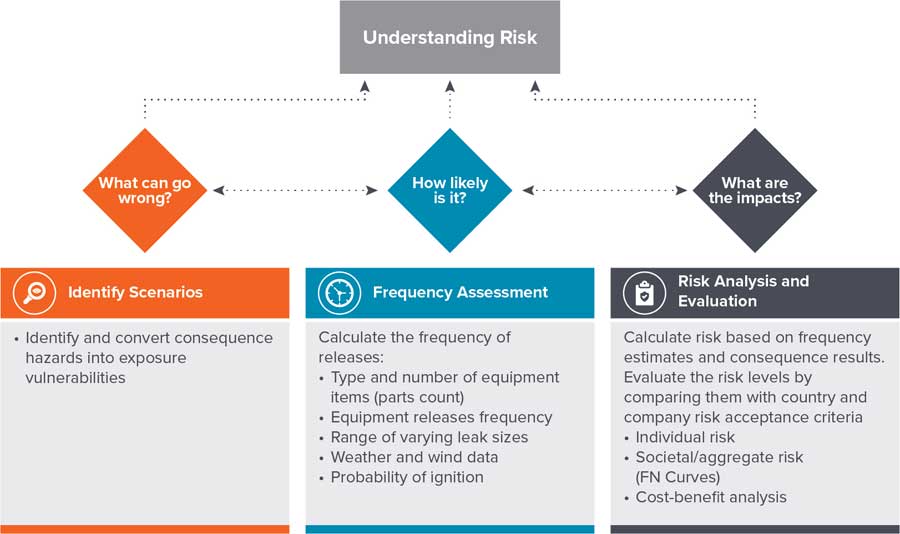

A Quantitative Risk Assessment (QRA) is a systematic approach to calculating risk. It provides a clear, quantifiable understanding of potential risk exposure to personnel, assets, the environment and your business. In addition, a QRA evaluates the validity of quantitative results by identifying critical assumptions and risk-driving elements. A QRA involves predicting the consequences of a hazard and the frequency at which the threat may occur. These aspects are then combined to obtain numerical values for fatality risk.

QRA studies are invaluable for production and processing facilities, high-pressure pipelines and storage and importation sites, including Liquefied Natural Gas (LNG).

Utilizing a risk-based approach for facility siting improves decision-making by highlighting scenarios that contribute most to your overall risk.

This approach ensures you meet acceptable individual, operational and environmental criteria demonstrating that risk is As Low As Reasonably Practicable (ALARP).

Implementing QRA: Going Beyond Software

When it comes to conducting QRAs, there are various commercial and private software tools. While these tools can identify hazards, quantify exposure and calculate risk, this is often where their capabilities stop, resulting in an unclear path forward. While you may better understand your hazard risk, the question of what to do next is not always apparent.

Common questions you may be left answering alone are:

- "How can additional modeling of select controlling scenarios improve my risk?"

- "How do I retrofit a building when I do not have design loads or occupancy established?"

- "Without clear hazard contours, where can I site blast-resistant buildings, trailers and other portable or temporary buildings?"

- "What is the best cost-effective solution to protect occupants of a building from hazards?"

A QRA is not just about having a software tool and running complex multivariate analysis. You need practical experience in deriving points of action from the QRA so that you can properly manage your operational risk. The QRA process should identify the hazard source so you can develop emergency response plans, adjust occupancy retrofit structures, locate new permanent and temporary buildings and install automated detection systems.

Our Unique Approach to QRA

ABS Group offers a global multidisciplinary network of engineers and a full scope of risk-based analysis experience and tools in a cradle-to-grave approach. In addition, we possess the ability to integrate detailed consequence modeling such as Computational Fluid Dynamics (CFD). Our QRA process utilizes a data-intensive approach in identifying scenarios by including all process equipment with hazard potential and modeling a wide range of release sizes and historical weather conditions.

We have developed software tools such as FACET3D, proprietary data analysis and frequency prediction spreadsheets to model a range of unique outcomes.

Understanding Your Risk

We offer our clients a three (3) step solution:

- Understand the Risk

- Analyze the Risk

- Mitigate the Risk

Below are the main steps involved in a typical QRA study, including how the outputs feed into the next phase of the process.

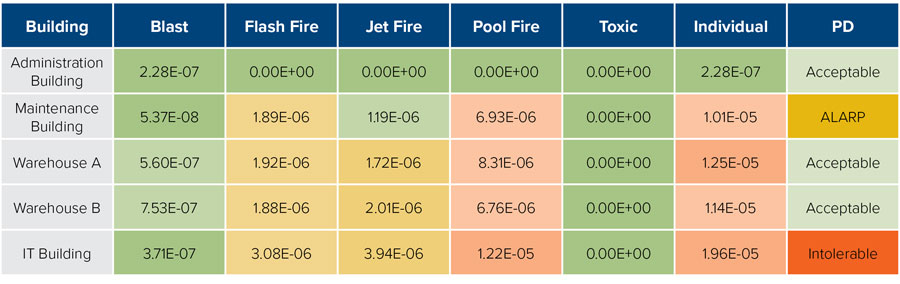

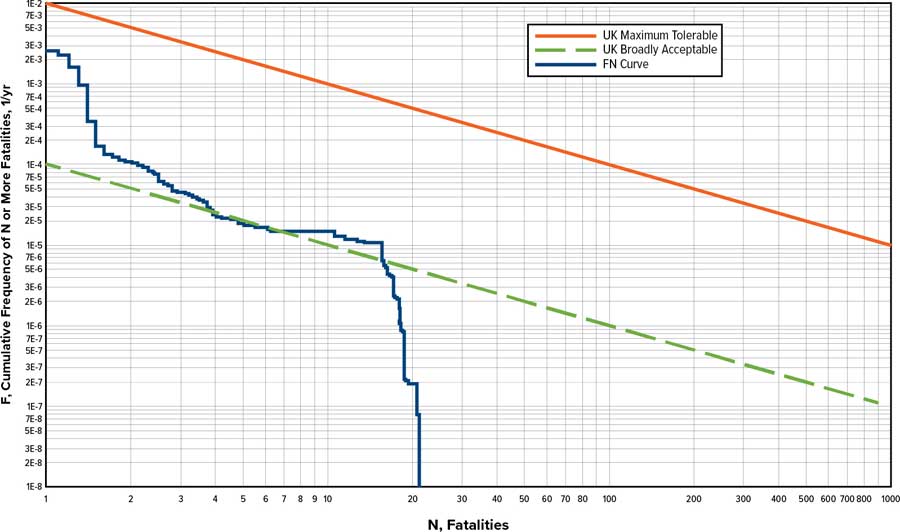

ABS Group provides our clients with a comprehensive, detailed report that defines inputs, explains calculation methodology and summarizes results in meaningful tables and figures (as shown below). We also offer mitigation options to target the most notable contributors to the total risk.

Why ABS Group?

ABS Group is uniquely positioned based on experience to provide clients with facility siting using risk-based methods. Risk-based facility siting offers a more rigorous study of potential significant accident hazards. It is crucial for industry PSM to understand the minimum requirements for a QRA and what to look for when interpreting QRA studies. Working with industry experts like us provides easy solutions to the complex issues surrounding QRAs.

Evaluating impacts and doing cost-benefit are usually the limits for most consultants. We offer a solution-focused approach, with the QRA being the starting point in the journey toward safer operations. Risk ranking and prioritization, mitigation planning, cost-benefit studies, design, and implementation planning, allow us to provide a turnkey solution for the facility siting lifecycle.