Optimizing Asset Reliability for Global Agribusiness Network

Read how we conducted a comprehensive gap analysis to identify asset reliability improvements, which led to a 22% reduction in total annual maintenance spend for an agricultural manufacturer operating in Asia, Europe, North America and South America.

Project Objectives

#1

Conduct a comprehensive analysis of over 70 operations sites to assess gaps in the asset reliability program

#2

Establish and document expectations for evolving the asset reliability program to improve performance in collaboration with organization's network of sites

#3

Define return on investment opportunities and recommended actions to support a tactical improvement plan that will lead to optimized asset reliability performance improvement

Project Overview

A global manufacturer of agricultural products needed to improve its asset reliability program across a global network of sites in order to reduce maintenance spending and increase operational efficiency.

GenesisSolutions worked closely with the client to conduct a comprehensive gap analysis of over 70 operations sites, develop tactical improvement plans for optimizing work management processes, systems

Client Needs

- Identify gaps in reliability performance, with the goals of reducing maintenance spending and increasing efficiency

- Develop a long-term asset reliability and performance optimization strategy

Our Solution

Apply Asset Reliability Methodology

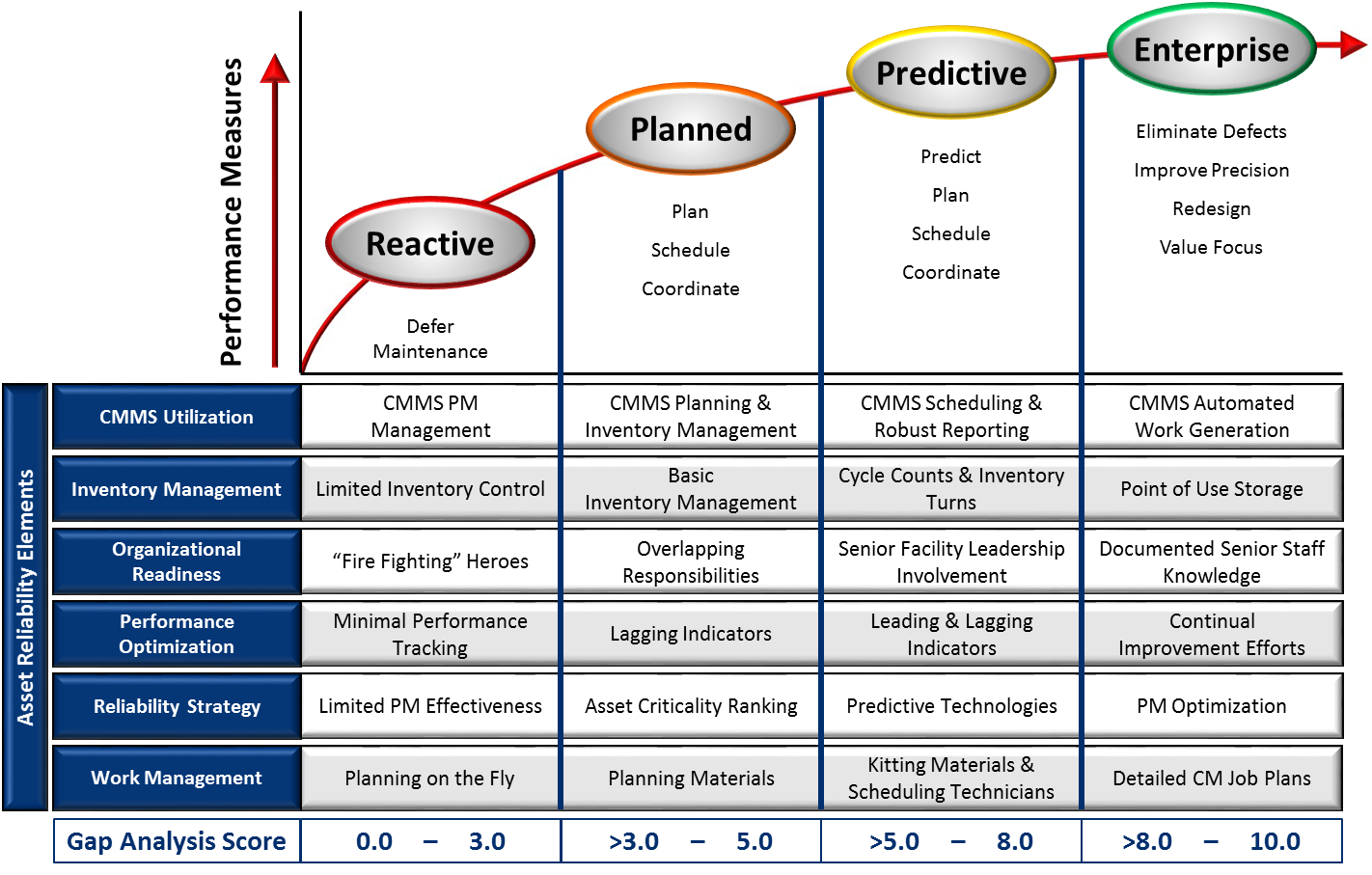

As a part of the Six Sigma DMAIC process (Define, Measure, Analyze, Improve and Control) used to develop our improvement methodology, GenesisSolutions first defines a maturity continuum comprising six core elements of asset reliability. The spectrum that represents the maturity continuum depicts a range of operational state: from

- CMMS Utilization

- Inventory Management

- Organizational Readiness

- Performance Optimization

- Reliability Strategy

- Work Management

Perform Asset Reliability Gap Analysis

Our asset reliability team worked with the customer to deliver both a detailed and effective gap analysis across a network of over 70 operating sites. As part of the project work scope, our professionals met with the senior managers who led the analysis in each location, walked through facilities to observe operations, collected CMMS data, facilitated working sessions, reviewed technical documents, conducted

Create Scorecard and Document Recommended Actions

Once our team scored the customers' asset reliability criteria and reviewed the gap analysis results, we were able to develop the necessary recommended actions for improving the company's maintenance and reliability program.

To promote success in defining the tactical improvement plan, we calculated and prioritized which actions could benefit the customer in terms of improving performance and reducing maintenance costs.

Develop and Implement Tactical Improvement Plan

As part of this deliverable, GenesisSolutions compiled the data into a report that summarized where the organization ranks in terms of the specified asset reliability components identified as critical to operational success and return on investment.

In this case, a scorecard was developed and used as the basis for the tactical improvement plan, a comprehensive project outline providing detailed steps for each improvement action and the subsequent tasks that need to be executed and measured by key performance indicators to drive productivity savings.

Depending on operations, tactical improvement plans may be initiated and carried out in clearly defined phases to promote greater efficient and more effective implementation.

Value Delivered

Delivering Targeted Savings

Our Asset Performance Optimization team identified opportunities to reduce the client's total network annual maintenance spend by 22%.

To improve operational efficiency and reliability while cutting maintenance costs, we helped a major customer in the food and agricultural business assess over 70 sites across a global network of production facilities. The goals of the gap analyses were to identify areas for improvement, quantify the savings potential and create a tactical improvement plan to guide each site's implementation