Manufacturing

Gain Competitive Advantage with Asset Reliability

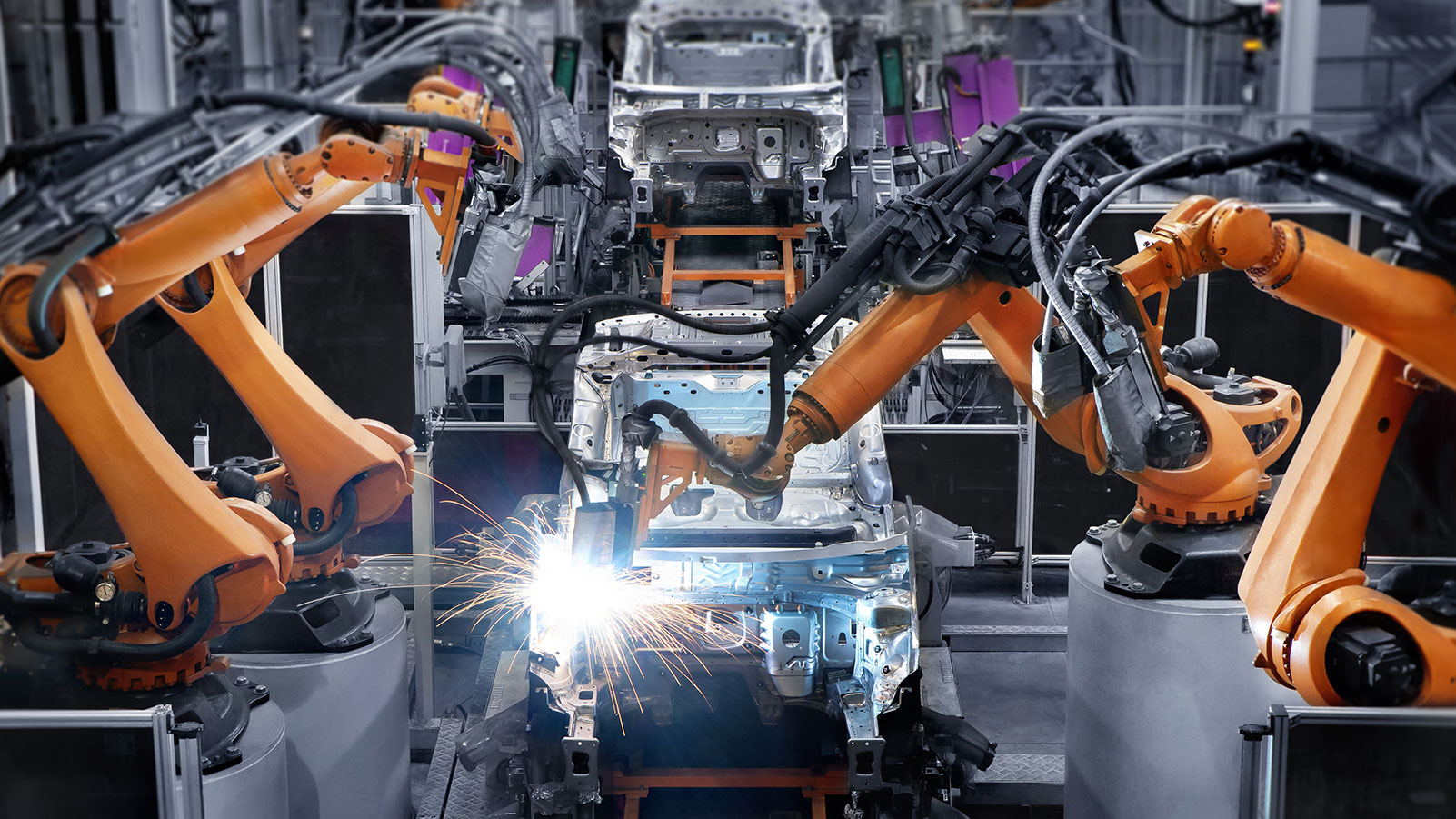

Manufacturers must produce the highest quality product, in the shortest amount of time, at the lowest possible cost and in the most responsible manner. We address areas such as product quality, production lead time, delivery, costs and social responsibility, maximizing these key factors to help our customers remain competitive in the global economy.

Maximizing Production Uptime for Manufacturers

When you need to depend on your equipment to produce a quality product at the rated volume, you need a proven maintenance strategy. GenesisSolutions helps manufacturing facilities develop enterprise asset management strategies to maximize equipment life and minimize planned and unplanned downtime. While some manufacturing companies may not require validation services, we apply our same quality processes to help customers in this industry maintain consistent products that are delivered on time, within budget and in a compliant, environmentally responsible manner.

Facility Maintenance Management

Facility Maintenance Management

We assist a variety of manufacturing facilities and process industries with transitioning from manual procedures to a CMMS to improve asset management, workflow, maintenance operations and quality control. We also upgrade existing systems for greater efficiency and improved performance.

Supporting Capabilities and Infrastructure

Supporting Capabilities and Infrastructure

We provide capabilities and infrastructure support services to global manufacturers. Our scope of work includes the automation of inventory and material reordering processes, reduction in resource labor time, departmental consolidation, software deployment, workflow streamlining and work request alignment.

Reliability Services for Manufacturing Sector

Reliability Services for Manufacturing Sector

Our reliability team has helped manufacturing facilities improve their maintenance work processes, implement reliability engineering programs, establish maintenance best practices, define asset lifecycle management programs and perform criticality analyses to enable more effective and reliable operations.

A Fully Integrated EAM Services Provider

Asset Integrity and Reliability

GenesisSolutions helps customers in the manufacturing industry establish asset reliability programs to monitor and manage asset dependability though integrity. We apply award-winning processes to assess the current condition and then develop a plan to achieve asset integrity goals. Our asset reliability services also include applying traditional techniques such as FMEA and developing predictive maintenance programs.

Enterprise Asset Management

A comprehensive program to support asset health is critical in assuring asset performance. GenesisSolutions helps companies develop EAM programs that remove guesswork and apply proven science so customers know where and when to take action. EAM program services include inventory optimization, PM optimization, planning and scheduling, and structured work management processes.

CMMS Implementation

GenesisSolutions is a full service CMMS solutions provider that has forged strategic alliances with leading software companies such as IBM and Infor, as well as many of their third party providers. We work closely with customers during the early selection phases through preparation, implementation and support of their CMMS. Our expertise and CMMS services cover organization change management and training program development to assure that the implemented system becomes a part of the company's culture.

Data Services

Maintaining quality data is at the center of any business program. We provide services to collect missing data and improve and/or correct low quality data. Our teams can physically walk down assets, inventory or documents to collect data and/or we can electronically cleanse data. We also help companies establish long-term programs to keep data quality high once our teams perform their work.

Award-winning Reliability Engineering Solution

Our service model is built on a risk based approach to optimizing asset performance management strategies. To quantify the risk profile across a broad range of assets and facilities in the Manufacturing sector, we have developed a robust asset criticality ranking tool which was awarded the 2015 Solution Award for Reliability Engineering. The tool is used to rank assets based on their criticality to the business or operation.

Product deliverables include:

- Evaluation of how asset failures impact organizational performance

- Provision of detailed profiles of characteristics that makes each asset critical

- Allowance for systematic ranking of assets for prioritization efforts

Our initial efforts are focused on the first quartile of critical assets where we work to ensure that we maintain the most critical assets with the leanest and unobtrusive maintenance strategies to minimize residual risk while maximizing asset performance.